Covid-19 Airway Management Isolation Chamber (CAMIC)

September 30, 2021 | Download PDF

COVID-19 has drastically changed the world. Its airborne spread and prolonged, silent transmission have wreaked havoc on an unprepared enterprise - the military was no exception. During the early phases of the outbreak, hospitals struggled to increase personal protective equipment (PPE), and frequent exposures decreased the number of available healthcare workers. This threat remains as novel variants cycle through populations.

Physicians that work close to patients’ airways are particularly vulnerable. At the start of the pandemic, PPE was hard to come by and had to be rationed and reused. Well established airway algorithms were abandoned and instead early intubation and mechanical ventilation was initially advocated to treat COVID patients. This created an artificial demand for ventilators as high flow oxygen, nebulizers and positive pressure (CPAP/BiPAP) were often skipped. Innovation was abundant in hospitals around the world to find solutions to many of these problems.

During the first few weeks of the pandemic, a group of Army physicians developed a novel device to help protect healthcare workers and act as an adjunct to reduce the spread of the virus. LTC Steven Hong, an Otolaryngologist at Walter Reed National Military Medical Center (WRNMMC), had envisioned a barrier device to potentially protect clinicians as they perform intubations. He shared this idea with several colleagues, and thus the COVID-19 Airway Management Isolation Chamber (CAMIC) was born. Working collaboratively together with LTC Douglas Ruhl, an Otolaryngologist at Madigan Army Medical Center; MAJ Paul Wistermayer, an Otolaryngology resident at Madigan Army Medical Center; MAJ Charles Riley, an Otolaryngologist at Fort Belvoir Community Hospital; CPT Timothy Blood and CPT Jonathan “Nate” Perkins, both Otolaryngology residents at WRNMMC; 2LT Joseph Krivda, a medical student at the Uniformed Services University; and Mr. Nathan Fisher, the Chief of the Medical Robotics and Autonomous Systems Division at TATRC CAMIC became a reality.

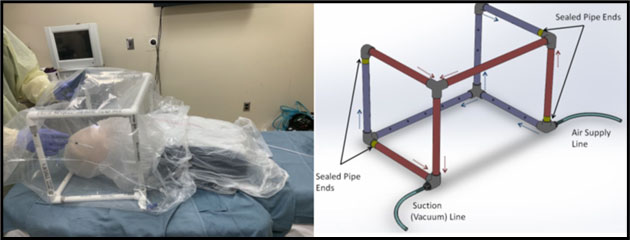

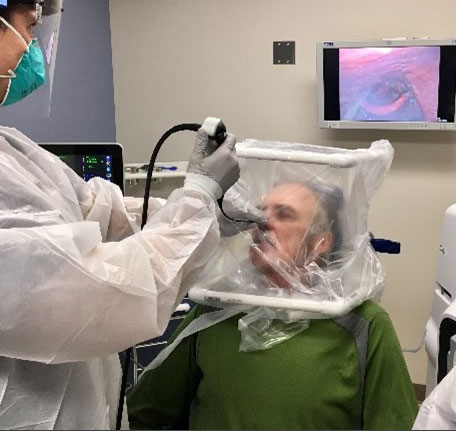

“It all started when LTC Hong called us. After brainstorming about this intubation barrier, we realized this idea could address several problems we faced while treating COVID patients”, said LTC Ruhl. They ultimately created CAMIC. It was a barrier device made of PVC pipe that attached to filtered suction and medical oxygen. The CAMIC contains air from around a patient’s head and actively removes particles – analogous to a small, portable negative pressure environment. “Since the CAMIC contains infective particles during airway treatments, like high-flow oxygen, a nebulizer, or a CPAP, it will hopefully decrease the need for ventilators by allowing physicians to return to more normal airway protocols”, said Ruhl.

The team of Army Physicians worked tirelessly – they created scientific protocols, made makeshift labs in their clinics and tested numerous prototypes. They slept in the hospital many nights and used virtual meetings to coordinate their efforts across the nation. They worked with several DoD organizations to obtain patents for the Army and to obtain FDA Emergency Use Authorization for their device in record time. “From identification of a dire problem, to a tested solution and product to bring forward to the FDA for clearance and two provisional patents along the way in less than 3 weeks’ time is unprecedented,” said Hong.

The AMTI funding from TATRC allowed this team of innovators to obtain particle detectors to facilitate their testing and 3D print various components to prototype. This coordinated development aligns perfectly with the core pillars of the AMTI Program: the CAMIC is a cost-effective device that is easily accessible to anyone; it has been tested and approved by the FDA and allows clinicians to safely perform their duty; and the device decreases the spread of disease which increases readiness. Scientific results were published in several medical journals. USAMRDC secured two domestic and one international patent for novel components on the CAMIC. The Army licensed the device to a civilian medical product company, PrepTech LLC, who manufactured the CAMIC for distribution across the country. The freely available assembly instructions, published effective, safety research, FDA backing, and optional commercial product, positively impacted the Military and Civilian healthcare systems.

Designs for the CAMIC were sent to clinicians in austere environments in USAFRICOM and devices were sent to Combat Support Hospitals in Iraq and Afghanistan. “The thing that really told us the significance of our project was hearing direct feedback from people that were deployed, that CAMIC was being used out in theater,” said Hong.

The CAMIC can also contain particles from infected patients as they move around the hospital or are in close quarters from others to minimize spread of disease. This may be of use on aircraft carriers to prevent outbreaks. Therefore, the next steps of our project aim to create a smaller, more portable device. Prototypes have been built and are being tested at TATRC and USAMMDA. Other clinical variations of the device have been used to safely perform surgeries such as tracheostomies, skull base surgery and airway procedures.

The CAMIC’s development team was recognized and received the Federal Laboratory Consortium’s “Excellence in Technology Transfer Award” – a competition among all federal laboratories. LTC Ruhl noted, “Overall, this was a stressful project that yielded remarkable results. It was incredible to have so many military organizations working in tandem for a common purpose. That allowed us to accomplish many things in a short amount of time and hopefully help others during this demanding health crisis.”

For more information on the AMTI Program, please reach out to AMTI Program Manager, Ms. Holly Pavliscsak at: holly.h.pavliscsak.ctr@mail.mil.

This article was published in the April 2022 issue of the TATRC Times.